Unfortunately, due to monolithic programms and just-theory-instructions prevelant in most universities around the globe and also thanks to more practical skills and knowledge demanded in oil and gas industry, process/mechanical engineering graduates, after graduation, and their subsequent entrance to refinaries and petrochemicals feel extremely disappointed in themselves why they have not learned such matters earlier and wished they have done more.

Unfortunately, due to monolithic programms and just-theory-instructions prevelant in most universities around the globe and also thanks to more practical skills and knowledge demanded in oil and gas industry, process/mechanical engineering graduates, after graduation, and their subsequent entrance to refinaries and petrochemicals feel extremely disappointed in themselves why they have not learned such matters earlier and wished they have done more.

Our “From Graduation to Industry“ program, which is all free of charge, is established to make their wishes come true. The program aims to not only help them boost their knowledge in practical subjects but also teach them how to put their academic and theoretical knowledge into practicalaties and as a result pave the way for their future.

Our “From Graduation to Industry“ program, which is all free of charge, is established to make their wishes come true. The program aims to not only help them boost their knowledge in practical subjects but also teach them how to put their academic and theoretical knowledge into practicalaties and as a result pave the way for their future.

Our “ From Graduation to Industry “ program, which is all free of charge, is established to make their wishes come true . The program aims to not only help them boost their knowledge in practical subjects but also teach them how to put their academic and theoretical knowledge into practicalaties and as a result pave the way for their future.

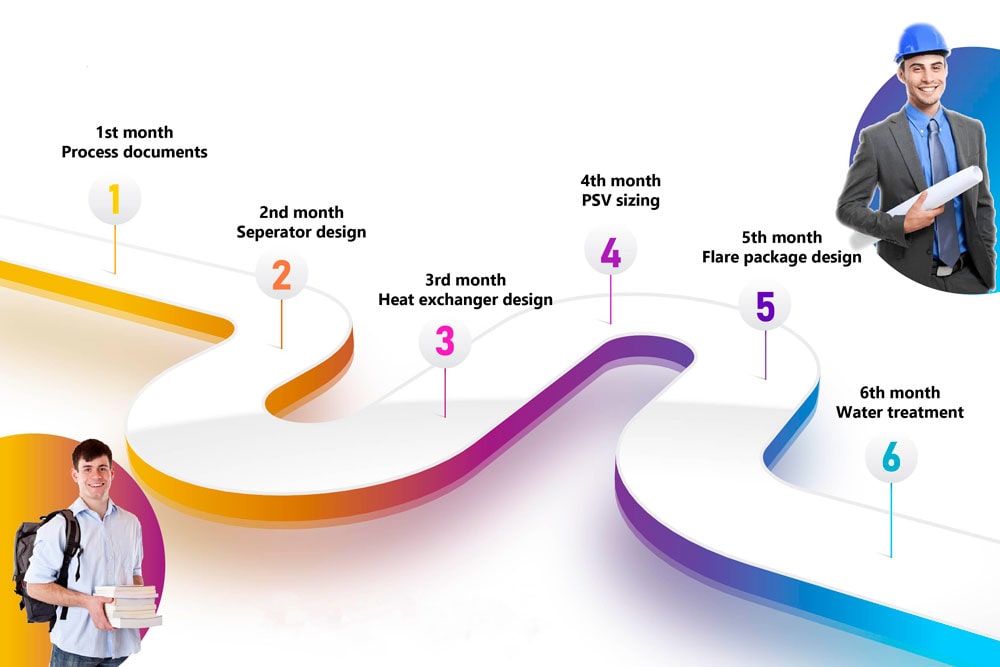

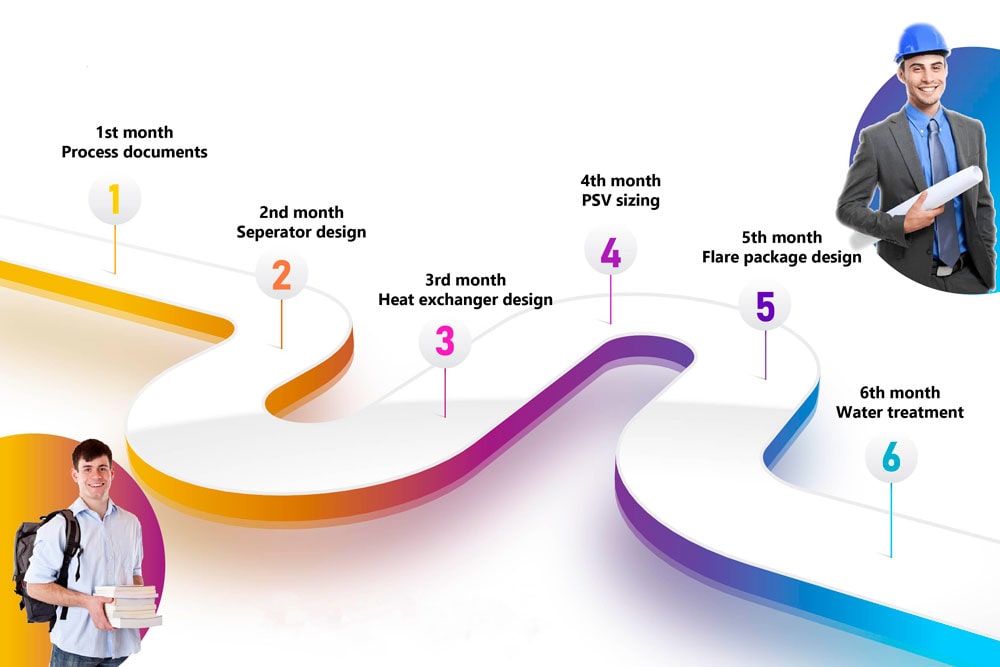

In first month of Graduation program, you will be trained to not only deal with project documents but prepare and develop them as well.

Here are the project documents you will master:

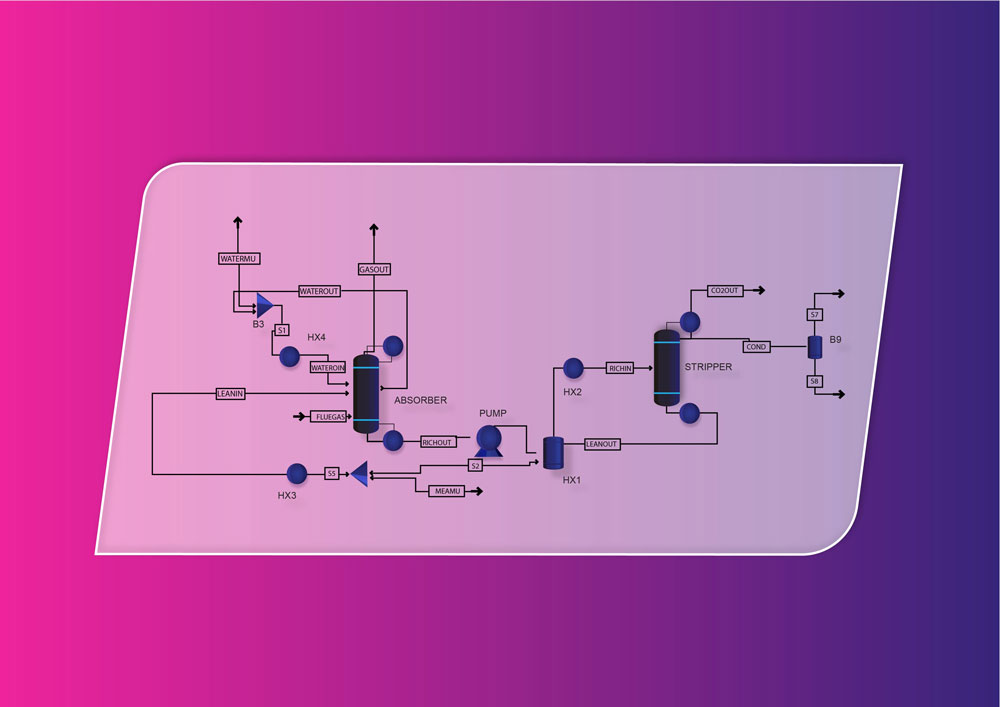

1. BFD-PFD-P&ID

2. Process design criteria

3. Pump and valve datasheet

4. Common processes and process control

5. Interlock and logic diagram

6. PSV instructions and flare header summary.

7. Simulation of pump and control valves in Aspen Hysys, Aspen Plus, and specialized software.

We promise to change your perspective towards simulation of process plants.

You know why our training is comprehensive?

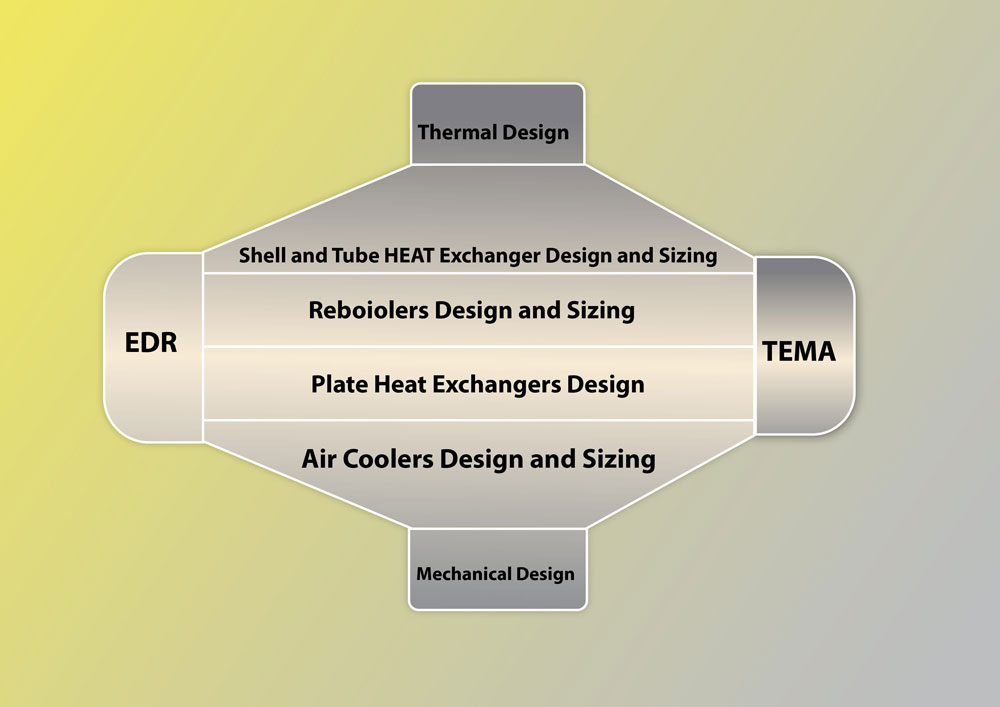

We process managers always wish the new hire have good knowledge about different components of heat exchangers and at least be a little familiar with industry software used for heat exchanger design.

Don’t worry, we make you professional overnight!

We not only instruct you the whole components of heat exchangers, but also teach you how to use industry software like professionals in a way you will be able to determine the baffle cut, the exact number of tubes, the shell ID and the list goes on.

We Make You Proud.

To be successful in your future job, you should always have operational perspective towards whatever you do.

This area is going to be completely new to you since there is literally no such training in academic courses.

In Graduation Program we will give you a comprehensive training about, site and control room activities during pre-commissioning, start-up, normal operation and shut-downs

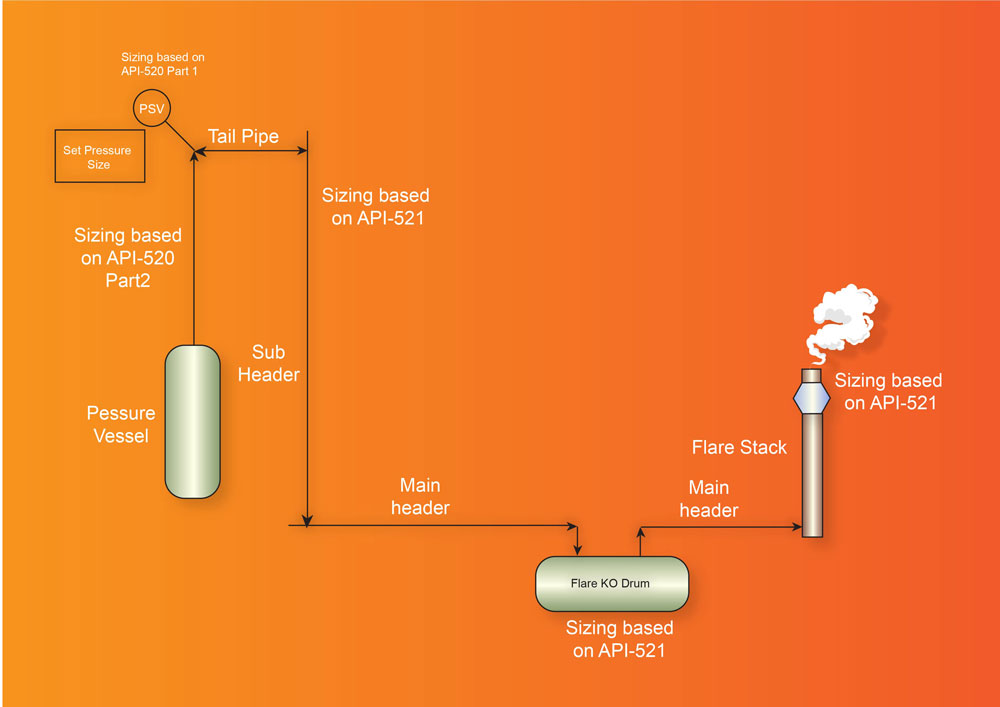

You see process plant design without process safety considered is a garbage. You might provide perfect process engineering services but when you don’t know about basics of process safety, protective and preventive measures, nobody is going to value your knowledge.

Throughout the Graduation Program you will gain deep understanding of APIs used, the prepared excel sheet, the software used, and how to size different components of flare package.

We Make You Proud.

As a fresh chemical engineering graduate, the “From Graduation to Industry” Learning Program provided by EIEPD has been very helpful for me in entering the work enviroment. I gained a lot of new knowledge about process engineering that I didn’t acquire at university. EIEPD taught me about designing separators, Process Design Criteria, Line sizing, PFD and P&ID development, PSV in a very friendly way . Now, I don’t feel confused or anxious when looking for job, instead I am more confident job interviews because I possess significantly more knowledge and skills than my peers.

As a fresh-graduate chemical engineer who has to learn a lot and fast to catch up with the current industrial standard, EIEPD has helped me a lot to gain practical insights on how to apply the knowledge that I have learned in school and those that I just learned through the course. The courses are filled with real-world case studies from which I can gain not just knowledge but experience, especially on how to make decisions regarding some details in equipment design and process design. I am forever grateful to EIEPD for this opportunity which will shape my career as a process engineer.

Their exceptional teaching style and deep expertise made the complex subject matter not only understandable but genuinely fascinating. Instructors’ dedication to their students’ success is evident in their clear explanations, engaging lectures, and unwavering support. The monthly projects of EIEPD is truly a confidence boosting. I feel more confident and inspired in the field of process engineering, thanks to their guidance. I am truly grateful for the valuable knowledge and positive learning experience they provided.

As a fresh chemical engineer, I’ve found the EIEPD curriculum’s focus on line sizing, equipment design and in-depth training on industry-standard software like Aspen Plus, KG Tower, and Fischer incredibly beneficial. The course not only provided theoretical knowledge but also hands-on experience, equipping me with the practical skills required in the field. The instructors’ expertise and the program’s structure have been instrumental in my professional development.I wholeheartedly recommend EIEPD to any aspiring chemical engineer seeking a structured, monitored, and practical education in these vital areas of expertise.

I had the opportunity to be part of the program “From Graduation to Industry” in which we were taught to elaborate and develop Process flow Diagrams (PFD), Piping and Instrumentation Diagrams (P&ID), Sizing of lines, control valves and safety valves (PSV) and their respective data sheets, besides that we have seen simulations of different equipment in Aspen Plus and Hysys. I am very grateful for all the knowledge they have shared with us to help us land our dream jobs.

After completing my degree in process engineering, my enthusiasm for designing process plants and simulating them began to flourish. Unfortunately, I struggled to find a platform that could help shape my skills and provide the necessary knowledge. That’s when I discovered EIEPD, and it turned out to be a life-changing platform. Now, I can confidently size separators using methods such as GPSA, Svrcek, and EIEPD. I’ve become familiar with API standards and process design criteria. Beyond just reading, I’ve learned to design Process Flow Diagrams (PFDs) and Piping and Instrumentation Diagrams (P&IDs), considering factors like line sizing, site conditions, and interlocks. Additionally, I’ve gained the expertise to prepare pump and valve datasheets, among other valuable skills. The platform condensed years of experience into just a few months with an incredible methodology. I strongly believe that this platform is a must for every process engineer.

As a fresh chemical engineering graduate, the “From Graduation to Industry” Learning Program provided by EIEPD has been very helpful for me in entering the work enviroment. I gained a lot of new knowledge about process engineering that I didn’t acquire at university. EIEPD taught me about designing separators, Process Design Criteria, Line sizing, PFD and P&ID development, PSV in a very friendly way . Now, I don’t feel confused or anxious when looking for job, instead I am more confident job interviews because I possess significantly more knowledge and skills than my peers.

As a fresh-graduate chemical engineer who has to learn a lot and fast to catch up with the current industrial standard, EIEPD has helped me a lot to gain practical insights on how to apply the knowledge that I have learned in school and those that I just learned through the course. The courses are filled with real-world case studies from which I can gain not just knowledge but experience, especially on how to make decisions regarding some details in equipment design and process design. I am forever grateful to EIEPD for this opportunity which will shape my career as a process engineer.

Their exceptional teaching style and deep expertise made the complex subject matter not only understandable but genuinely fascinating. Instructors’ dedication to their students’ success is evident in their clear explanations, engaging lectures, and unwavering support. The monthly projects of EIEPD is truly a confidence boosting. I feel more confident and inspired in the field of process engineering, thanks to their guidance. I am truly grateful for the valuable knowledge and positive learning experience they provided.

As a fresh chemical engineer, I’ve found the EIEPD curriculum’s focus on line sizing, equipment design and in-depth training on industry-standard software like Aspen Plus, KG Tower, and Fischer incredibly beneficial. The course not only provided theoretical knowledge but also hands-on experience, equipping me with the practical skills required in the field. The instructors’ expertise and the program’s structure have been instrumental in my professional development.I wholeheartedly recommend EIEPD to any aspiring chemical engineer seeking a structured, monitored, and practical education in these vital areas of expertise.

I had the opportunity to be part of the program “From Graduation to Industry” in which we were taught to elaborate and develop Process flow Diagrams (PFD), Piping and Instrumentation Diagrams (P&ID), Sizing of lines, control valves and safety valves (PSV) and their respective data sheets, besides that we have seen simulations of different equipment in Aspen Plus and Hysys. I am very grateful for all the knowledge they have shared with us to help us land our dream jobs.

After completing my degree in process engineering, my enthusiasm for designing process plants and simulating them began to flourish. Unfortunately, I struggled to find a platform that could help shape my skills and provide the necessary knowledge. That’s when I discovered EIEPD, and it turned out to be a life-changing platform. Now, I can confidently size separators using methods such as GPSA, Svrcek, and EIEPD. I’ve become familiar with API standards and process design criteria. Beyond just reading, I’ve learned to design Process Flow Diagrams (PFDs) and Piping and Instrumentation Diagrams (P&IDs), considering factors like line sizing, site conditions, and interlocks. Additionally, I’ve gained the expertise to prepare pump and valve datasheets, among other valuable skills. The platform condensed years of experience into just a few months with an incredible methodology. I strongly believe that this platform is a must for every process engineer.

Educational Institute for

Equipment and Process Design

We at EIEPD show you the way to become professional in oil and gas industry